Why Carbon Nanofibers (CNFs) Matter in Advanced Manufacturing Today?

Advanced manufacturing continues to evolve at a rapid pace. Industries now demand materials that are lighter, stronger, more conductive, and more durable than ever before. Traditional materials such as steel, aluminum, and standard polymers still play an important role. However, they often fall short when performance requirements increase. This gap has pushed engineers and manufacturers to explore nanoscale materials that deliver exceptional results.

Among these materials, Carbon Nanofibers (CNFs) stand out as a practical solution already making an impact across multiple industries. They bridge the gap between laboratory innovation and real-world manufacturing. Because of this balance, many engineers now view them as a material that supports both performance and scalability.

This article explains why CNFs matter today, how they work, where they are used, and how manufacturers can adopt them effectively.

Understanding Carbon Nanofibers at the Structural Level

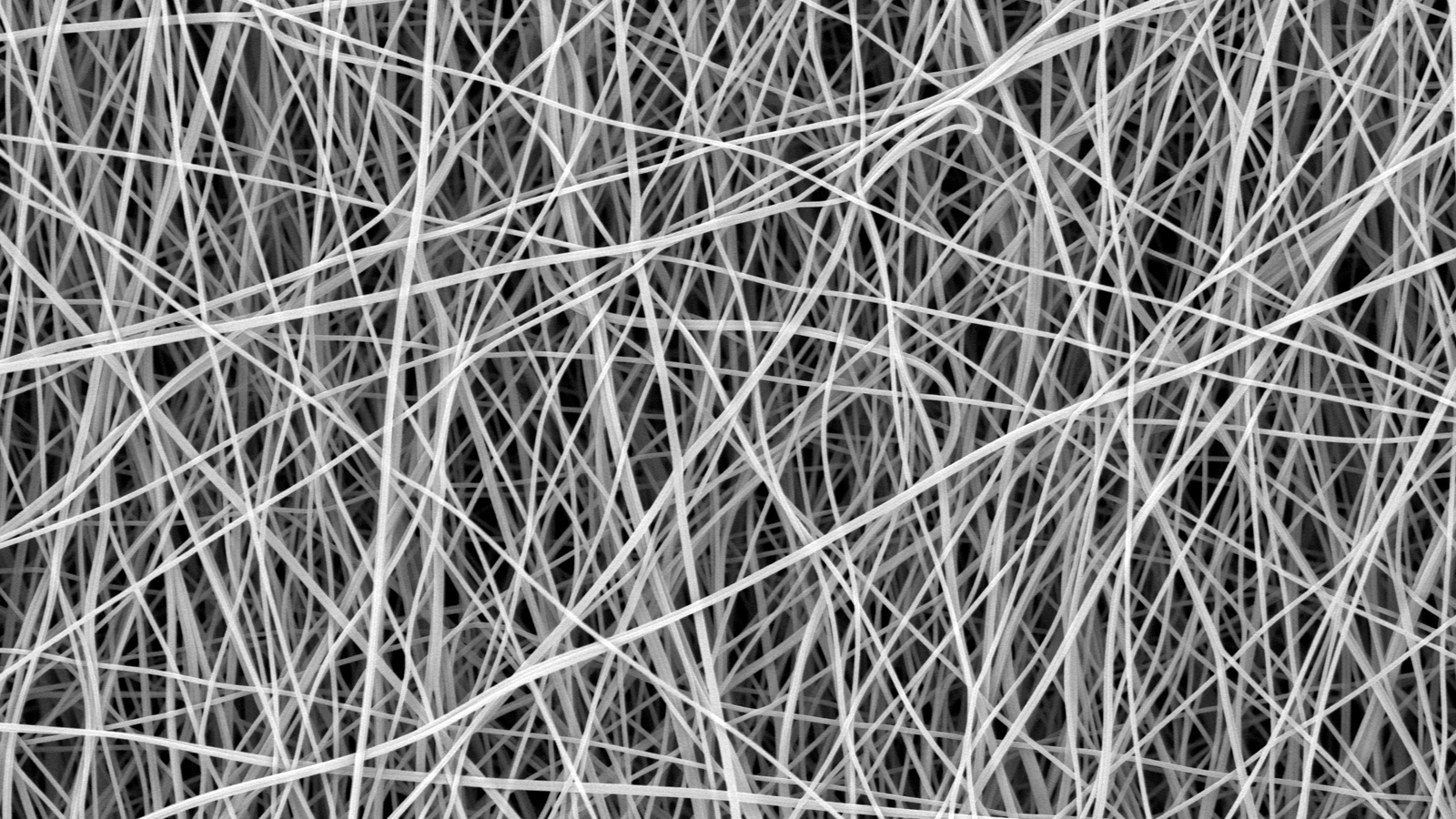

Carbon nanofibers are cylindrical structures composed primarily of graphitic carbon layers. Unlike bulk carbon materials, these fibers exist at the nanometer scale, which dramatically changes how they behave.

Their diameter typically ranges from tens to hundreds of nanometers, while their length extends into the micrometer range. This high aspect ratio plays a major role in their performance.

At the atomic level, carbon atoms bond through strong covalent bonds arranged in graphitic planes. Many studies describe their composition using simplified representations of carbon networks rather than fixed molecular formulas.

In research literature, they are often expressed as extended carbon frameworks, commonly simplified as Cₙ, where n represents a large number of bonded carbon atoms forming continuous layers. This structure explains their high strength, electrical conductivity, and thermal stability.

Because of this atomic arrangement, resist mechanical deformation while maintaining flexibility. As a result, they integrate well into composites, coatings, and functional materials without losing performance.

Why Strength-to-Weight Ratio Changes Manufacturing Design?

One of the biggest reasons CNFs matter lies in their exceptional strength-to-weight ratio. Manufacturers constantly look for ways to reduce weight while preserving strength. This challenge becomes even more critical in sectors such as aerospace, automotive, and robotics.

CNFs reinforce polymers and resins by forming interconnected networks inside the matrix. These networks distribute stress evenly rather than allowing cracks to propagate. As a result, composite parts become stronger without becoming heavier. Engineers can redesign components using thinner sections while still meeting safety and durability requirements.

Moreover, lighter parts reduce energy consumption during operation. Vehicles require less fuel, machines operate more efficiently, and structural loads decrease across systems. Therefore, the material contributes not only to performance but also to long-term operational savings.

Electrical and Thermal Performance That Supports Smart Manufacturing

Modern manufacturing increasingly relies on electrically and thermally functional materials. Sensors, automation systems, and smart components all require stable conductivity. CNFs deliver this capability by forming conductive pathways at very low loading levels.

When dispersed properly, these fibers create percolation networks that allow electrons to move efficiently. Unlike traditional fillers, they achieve conductivity without compromising mechanical integrity. This property makes them ideal for antistatic coatings, electromagnetic interference shielding, and conductive composites.

Thermal management also benefits from their structure. Heat travels efficiently along graphitic layers, which helps dissipate excess thermal energy. As electronics become smaller and more powerful, managing heat becomes essential. Manufacturers now incorporate carbon nanofibers into housings and substrates to prevent overheating and extend product lifespan.

Role in Energy Storage and Advanced Electronics

Energy storage technologies continue to expand alongside renewable energy and electric mobility. Batteries, supercapacitors, and hybrid storage systems require materials that support fast charge transfer and structural stability.

Their high surface area allows ions to interact efficiently during charge and discharge cycles. At the same time, their mechanical strength helps maintain electrode integrity over repeated use. Many electrode designs use fibrous carbon networks to improve cycle life and power density.

In advanced electronics, these fibers support flexible circuits, conductive inks, and lightweight connectors. Because they bend without breaking, they work well in wearable devices and compact electronic assemblies. This flexibility aligns with the growing demand for portable and adaptable technology.

Manufacturing Compatibility and Scalability

New materials only succeed when they integrate into existing manufacturing processes. CNFs perform well in this area. Manufacturers can introduce them into polymer compounding, resin infusion, and coating systems with minimal changes.

They disperse effectively using standard mixing techniques when surface-treated or properly processed. As a result, companies avoid costly equipment upgrades. This compatibility shortens development cycles and speeds up commercialization.

Additionally, production methods such as chemical deposition and catalytic growth continue to improve. These advances help control fiber morphology and purity while supporting larger-scale output. Over time, this progress reduces cost barriers and expands industrial adoption.

Practical Tips for Manufacturers Considering Carbon Nanofibers

Manufacturers exploring carbon nanofibers should follow a structured approach. First, material selection matters. Fiber diameter, length, and surface characteristics influence performance. Engineers should match these properties to the target application.

Second, dispersion quality directly affects results. Poor dispersion reduces conductivity and mechanical strength. Using proper mixing protocols and compatible binders ensures consistent performance.

Third, testing under real operating conditions remains essential. While lab data provides guidance, real-world stresses often reveal additional insights. Fatigue, thermal cycling, and environmental exposure tests help validate long-term reliability.

Finally, collaboration between material suppliers and design teams accelerates success. Early involvement allows engineers to optimize formulations rather than retrofitting materials later.

Environmental and Sustainability Considerations

Sustainability now plays a central role in manufacturing decisions. CNFs contribute positively when used strategically. By reducing material usage and enabling lightweight designs, they lower overall resource consumption.

Longer product lifespans also reduce waste. Components reinforced with nanofibers resist wear and degradation, which delays replacement cycles. Additionally, ongoing research focuses on improving synthesis efficiency and reducing energy use during production.

As regulations tighten and sustainability targets rise, materials that support both performance and environmental responsibility gain importance.

The Future Outlook for Carbon Nanofibers in Manufacturing

The future of advanced manufacturing points toward multifunctional materials. CNFs fit this direction well. They combine mechanical reinforcement, electrical conductivity, and thermal management in a single material system.

As digital manufacturing, automation, and smart factories expand, materials must perform multiple roles simultaneously. CNFs help meet these demands without increasing system complexity. Their versatility supports innovation across industries, from transportation to electronics and energy.

Ongoing research continues to refine their properties and expand application areas. With each advancement, their relevance in manufacturing grows stronger.

A Material That Supports Modern Manufacturing Needs

Advanced manufacturing depends on materials that deliver more without adding complexity. Carbon nanofibers matter because they strengthen structures, enhance functionality, and integrate smoothly into existing processes. They enable lighter designs, smarter systems, and longer-lasting products.

As industries move toward efficiency, sustainability, and innovation, carbon nanofibers provide a reliable foundation. Manufacturers that understand their potential and apply it strategically position themselves for long-term success.

In today’s competitive landscape, materials like these no longer represent future possibilities. Instead, they define how modern manufacturing moves forward.

0 Comments